Did you know that sprains and strains are the leading injury category in the manufacturing environment?

It’s true.

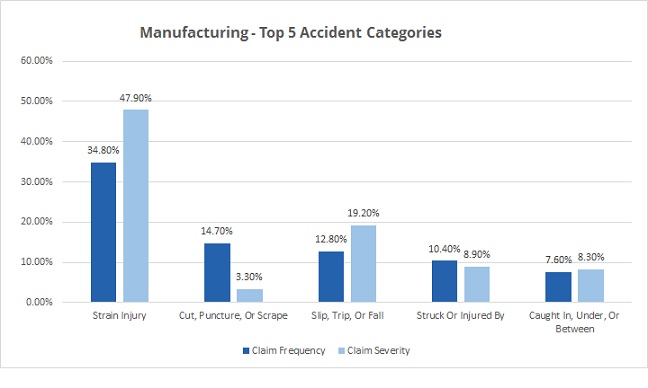

Not only that, but according to the worker’s compensation data, strains are the top accident category in manufacturing by claims frequency and severity.

Statistics on Sprains and Strains in the Workplace

Bureua of Labor Statistics (2011)

Bureua of Labor Statistics (2011)

Bureua of Labor Statistics (2011)

The data tells us that sprains and strains are common and costly in industry today. They are costly (and unacceptable) for businesses, they are costly (and painful) for workers and they are costly (and frustrating) for safety professionals.

If this situation rings true at your company, it’s time to make a decision to take proactive steps to take on these common and costly problems.

You’ll be happy to hear that sprains and strains are preventable in every workplace. What follows is a comprehensive (yet simple) approach to a complex problem.

It’s a simple matter of identifying risk factors and systematically implementing control measures.

The hard part is deciding to reduce all risk factors, gaining 100% leadership commitment and instituting a process that persists over the course of time.

Here is what you’ll find in this article:

- What are Sprains?

- What are Strains?

- The Causes of Sprains and Strains

- A Proactive, Prevention-focused Approach (Ergonomic and Individual Controls)

- Important — A Partnership Between a Company and its People

- Professional Prevention for Professional (Industrial) Athletes

- Key Takeaways

What are Sprains?

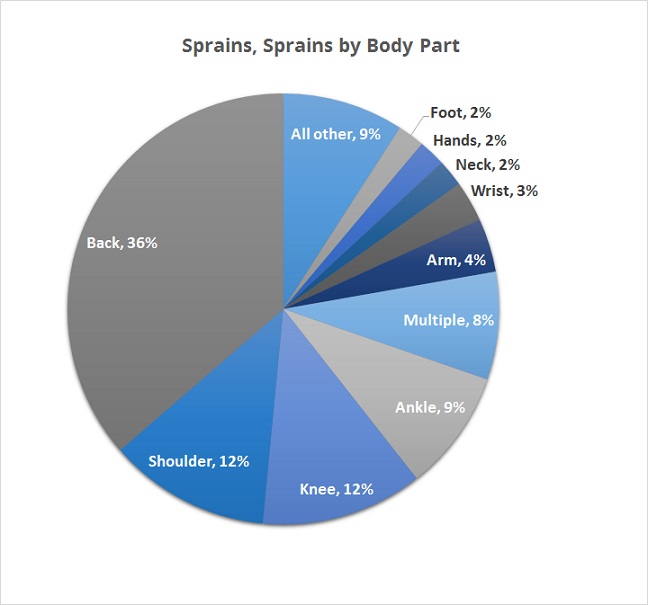

A sprain is an injury to a ligament (tissue that connects two or more bones at a joint). In a sprain, one or more ligaments is stretched or torn.

What are Strains?

A strain is an injury to a muscle or a tendon (tissue that connects muscle to bone). In a strain, a muscle or tendon is stretched or torn.

The Causes of Sprains and Strains

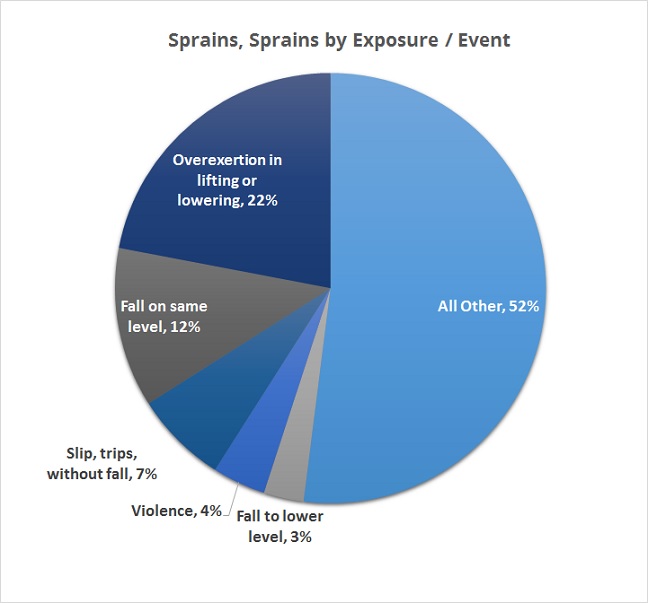

Sprains and strains can happen suddenly or develop over the course of days, weeks or months. When a worker is exposed to causative risk factors, they are more likely to develop a sprain / strain.

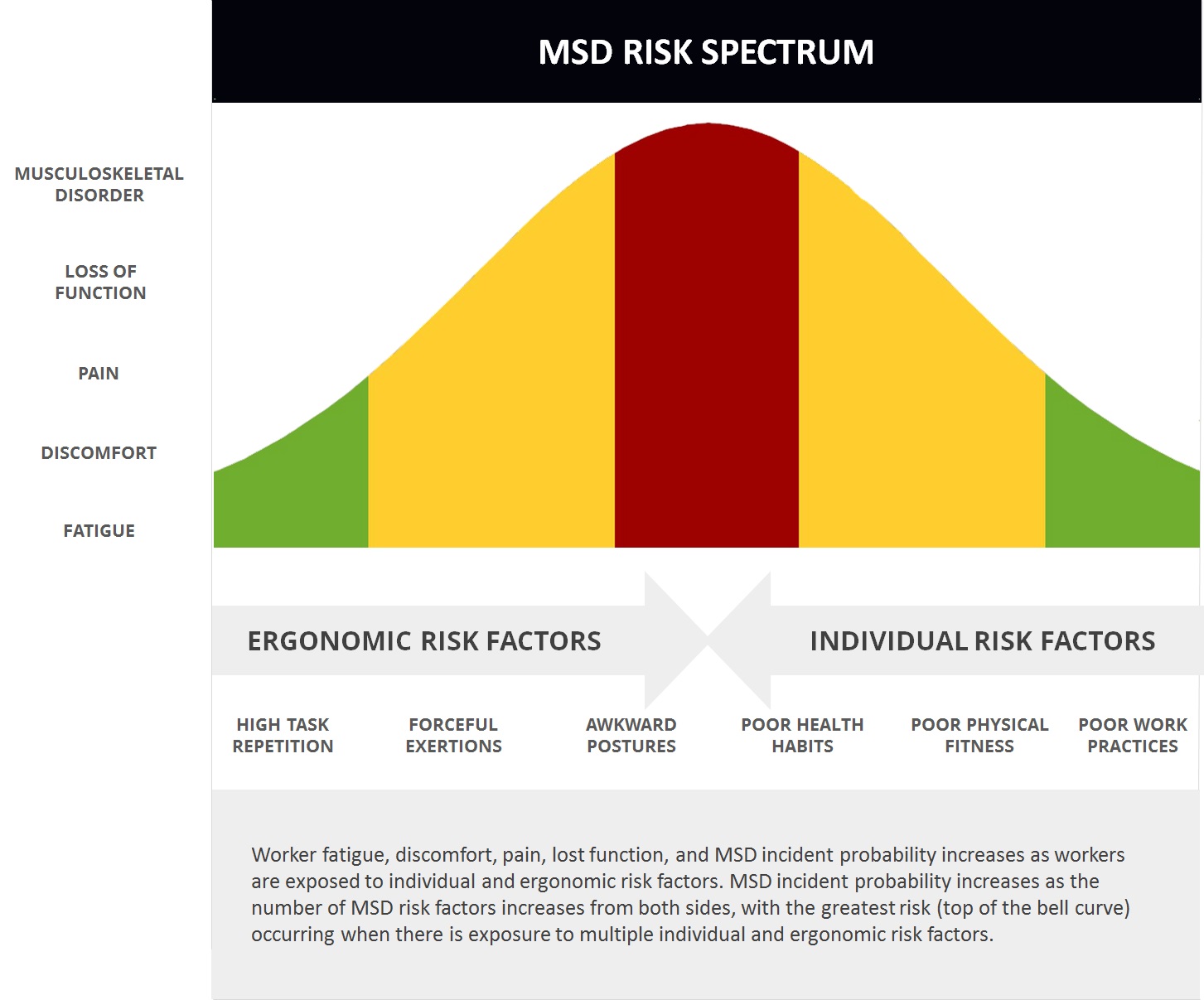

There are two general categories of risk factors; ergonomic (workplace) risk factors and individual risk factors.

Ergonomic (Workplace) Risk Factors:

- Excessive Force: Many work tasks require high force loads on the human body. Muscle effort increases in response to high force requirements, increasing associated fatigue which can lead to MSD.

- Excessive Repetition: Many work tasks and cycles are repetitive in nature, and are frequently controlled by hourly or daily production targets and work processes. High task repetition, when combined with other risks factors such high force and/or awkward postures, can contribute to the formation of MSD. A job is considered highly repetitive if the cycle time is 30 seconds or less.

- Awkward Posture: Awkward postures place excessive force on joints and overload the muscles and tendons around the effected joint. Joints of the body are most efficient when they operate closest to the mid-range motion of the joint. Risk of MSD is increased when joints are worked outside of this mid-range repetitively or for sustained periods of time without adequate recovery time.

- Other environmental factors: Slip, trip and fall hazards increase risk of a sudden / acute soft tissue injury.

Individual Risk Factors:

- Poor work practices. Workers who use poor work practices, body mechanics and lifting techniques are introducing unnecessary risk factors that can contribute to MSDs. These poor practices create unnecessary stress on their bodies that increases fatigue and decreases their body’s ability to properly recover.

- Poor overall health habits. Workers who smoke, drink excessively, are obese, or exhibit numerous other poor health habits are putting themselves at risk for not only musculoskeletal disorders, but also for other chronic diseases that will shorten their life and health span.

- Poor rest and recovery. MSDs develop when fatigue outruns the workers recovery system, causing a musculoskeletal imbalance. Workers who do not get adequate rest and recovery put themselves at higher risk.

- Poor nutrition, fitness and hydration. For a country as developed as the United States, an alarming number of people are malnourished, dehydrated and at such a poor level of physical fitness that climbing one flight of stairs puts many people out of breath. Workers who do not take care of their bodies are putting themselves at a higher risk of developing musculoskeletal and chronic health problems.

- No recognition of early signs and symptoms: Many MSDs develop over the course of time. At the first signs of excessive fatigue/discomfort, the worker has an opportunity to recognize the early signs and symptoms and proactively use recommended injury prevention tools and principles. Not recognizing early warning signs lends to a reactive approach – and it’s only a matter of time until these signs and symptoms develop into a musculoskeletal injury.

More Risk Factors, More Injuries

The more risk factors a worker is exposed to, the greater the likelihood of an injury occurring. As you can see from the MSD Risk Spectrum above, when both ergonomic risk factors and individual risk factors are present, the greater the likelihood of a musculoskeletal injury / disorder.

A Proactive, Prevention-focused Approach to Sprains and Strains in the Workplace

Prevention is, of course, better than treatment. Sprains and strains are a painful (and unnecessary) experience that we want to prevent from happening.

To do that, you need a comprehensive prevention process to systematically identify and remove the risk factors present in your workplace and workforce through the use of controls.

There are two primary types of controls; ergonomic (workplace) controls to reduce/remove ergonomic risk factors and individual controls to reduce/remove individual risk factors.

Ergonomic (Workplace) Controls

- Engineering Controls eliminate or reduce awkward postures with ergonomic modifications that seek to maintain joint range of motion to accomplish work tasks within the mid-range of motion positions for vulnerable joints. Proper ergonomic tools should be utilized that allow workers to maintain optimal joint positions.

- Administrative Controls include work practice controls, job rotation and counteractive stretch breaks.

Individual Controls

Just like putting controls in place to reduce ergonomic risk factors, you can put controls in place to reduce individual risk factors. We call them “individual controls”, and they control individual risk factors while also empowering individual workers.

- Education and Training Process: Employees should be trained on all aspects of human performance, including ergonomics, MSD prevention principles and individual health and wellness. Formal classroom training and one-on-one follow up ensures the message is getting through.

- Early Intervention Process: The early warning signs of future injuries are present in your workforce today. Early intervention is a proactive strategy designed to discover early warning signs of MSDs and prevent the early warning signs from developing into an injury. These one-on-one consultations with individual workers are often the last line of defense between risk factors present and an injury.

Important: A Partnership Between a Company and its People

The strategy outlined in this article for prevention of sprains and strains is a simple one — identify and control all contributing risk factors.

Putting ergonomic controls in place is part of the company’s responsibility to provide a safe workplace for their people.

In many cases, individual controls fall under the individual responsibility of the worker to keep his or her body fit for work and use proper work practices.

In over two decades of experience preventing sprains / strains (among many other types of MSD) in a manufacturing environment, the most successful companies I’ve seen have created a culture of safety, health and wellness. This culture is the result of each side of this partnership for prevention (the company and individual workers) taking responsibility for their role.

- Companies take responsibility for providing a workplace within the capabilities and limitations of workers through a systematic ergonomics improvement process and by instituting ergonomic design standards for new work tasks and processes.

- Workers take responsibility for keeping their bodies fit for the work they have chosen to do and they do their work well with proper work practices and technique.

Professional Prevention for Professional (Industrial) Athletes

To take prevention a step further, what if your employees were treated like professional athletes?

In the sports world, professional athletes are treated with utmost care. Team owners provide their athletes with injury prevention professionals, otherwise known as Certified Athletic Trainers (ATCs). The job of the athletic trainer is to keep the team healthy and performing at their best. After all, the success of the team depends on the health and performance of the athletes on the team.

In the same way, the success of your company hinges on the health and performance of the professional (industrial) athletes who do the work at your company. Perhaps it’s time you considered treating them like the professional athletes they are and providing them advanced care to prevent pain and injury.

Sprains and strain are common injuries in athletics, and athletic trainers are specifically trained in prevention of soft tissue injuries of all kinds. Bringing an athletic trainer into the workplace to prevent soft tissue injuries is a natural extension of their skillset.

It’s something to consider — what if your employees got the same treatment and care as professional athletes? What if an on-site prevention professional worked side-by-side with your employees, keeping them healthy and performing at their best?

Professional prevention for your professional (industrial) athletes. It’s worth careful consideration, especially if health and safety excellence is your goal.

Key Takeaways

- Sprains and strains in the workplace (and at home) are common and costly.

- Sprains and strains are caused by exposure to risk factors; ergonomic (workplace) risk factors and individual risk factors.

- Preventing sprains and strains in the workplace requires a simple strategy – reduce all causative risk factors by implementing controls; both ergonomic and individual controls.

- Fostering a culture of prevention at your facility is the best way to achieve prevention excellence.

- Certified Athletic Trainers are professional prevention specialists – engaging a prevention specialist at your facility can accelerate health and safety excellence.