A proactive MSD prevention process can turn a negative into a positive.

By implementing ergonomic and individual controls, you can reduce risk and prevent injuries. What you can also do is improve the human performance of your company.

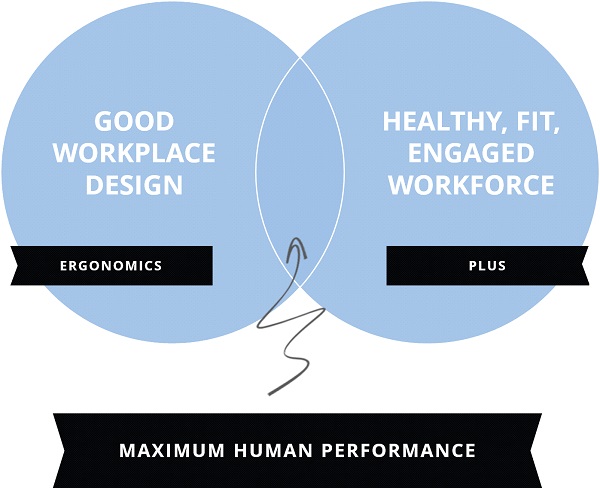

Maximum human performance is achieved at the intersection of good workplace design and a healthy, fit and engaged workforce.

An ergonomically efficient workstation with an unhealthy and unmotivated worker using poor work practices is not your goal. A healthy, motivated worker that is forced to work outside her body’s capabilities and limitations is not your goal.

Your goal has to be a well-designed and efficient workstation within the capabilities and limitations of a healthy, fit and engaged worker.

In other words, your company is responsible for providing a good “fit” between the work and the worker through ergonomics. The worker is responsible for using good work practices and staying fit so they can do their job. Health, safety, productivity and quality all depend upon this partnership between the company and the worker.

Ergonomics Plus exists to help our client’s and their employees meet their responsibilities to each other in this mutually beneficial partnership.

We call our methodology for injury prevention and human performance the E+ System. This comprehensive and hands-on approach to injury prevention and human performance has been developed from decades of experience and thousands of hours on the shop floor.

The E+ System has five elements, all designed to work together to identify ergonomic and individual risk factors and remove them through ergonomic and individual controls.

These elements are:

Establishment. Establishment is the foundation and blueprint for lasting MSD prevention success. All elements of the E+ System need to be customized into a process that integrates seamlessly with your existing business management processes and embeds a culture of prevention and wellness.

Education. Education and training ensures you have a well-trained and well-equipped workforce to support the process. Group training and one-on-one follow up sessions make sure the message is getting through and that learning objectives are being translated into real-world skills.

Early Intervention. We know that MSDs develop over the course of time – this means that the early warning signs of future injuries are present in your workforce today. Early intervention is a proactive strategy to discover early warning signs of future injuries and put control measures in place to prevent them.

Ergonomics. The ergonomics improvement process systematically identifies and removes ergonomic risk factors contributing to MSDs. The goal is to make continuous improvement to the workplace to make sure each workstation is within the capabilities and limitations of the employee you are asking to do the job.

Evaluation. Results are the name of the game. Monthly and annual evaluations of the process provide insight for continuous improvement opportunities and proof of the effectiveness of the process.

In Conclusion

The economic costs of MSDs are unacceptable and the human costs of MSDs are unforgivable. Accepting a comprehensive definition of “musculoskeletal disorder” and understanding causative risk factors of MSDs will set the foundation for a prevention strategy that bears fruit.

Musculoskeletal disorders are preventable. Take a proactive approach to MSD prevention and you can turn a negative (painful injuries) into a positive (improved overall human performance.)

The comprehensive benefits of good workplace design matched with a healthy, fit and engaged worker cannot be overlooked. In fact, the well-being and performance of your people underpins your company’s well-being and success now and into the future. Unleash your human capital through the science of ergonomics and the art of creating a culture of safety and wellness.

Think prevention!