The following NIOSH Lifting Equation Example is from the NIOSH Lifting Equation Applications Manual and has been adapted to show the proper use of the NIOSH Lifting Equation inside the ErgoPlus Platform.

In addition, this example shows how this tool can be used to evaluate body mechanics recommendations and ergonomic redesign suggestions.

To help you follow along, here are links to download our free guides to recommended ergonomic assessment tools and to create a free ErgoPlus Platform account to use the NIOSH Lifting Equation software tool inside.

Now let’s get to work on the example:

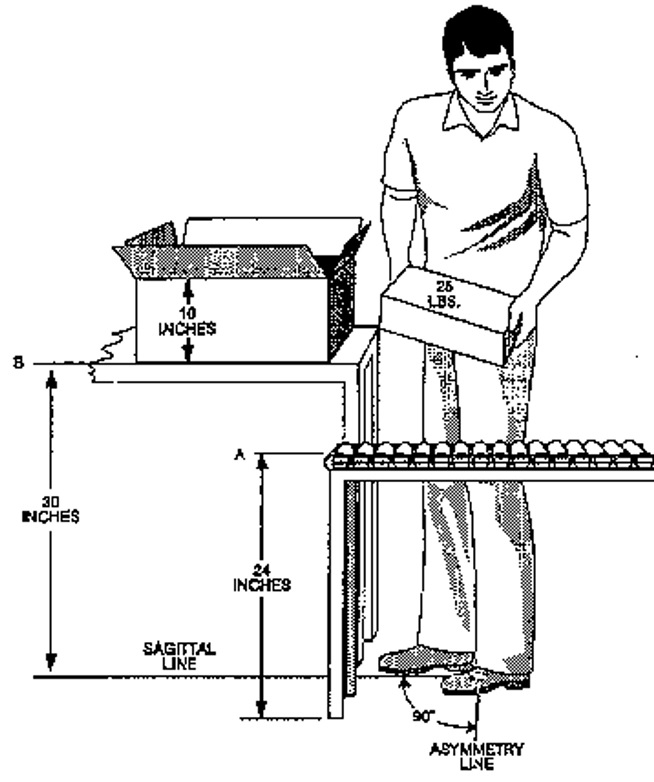

Job Description

In the job illustrated below, products weighing 25 lb. arrive via a conveyor at a rate of 1 per minute, where a worker packages the product in a cardboard box and then slides the packaged box to a conveyor behind table B. Assume that significant control of the object is not required at the destination, but that the worker twists to pick up the product; also assume that the worker can flex the fingers to the desired 90 degrees angle to grasp the container. The job is performed for a normal 8-hour shift, including regular rest allowance breaks.

Data Collection and Job Analysis

At the origin, the vertical location (V) is 24 inches and the horizontal location is 14 inches. At the destination, the vertical location is 40 inches, which represents the height of table B plus the height of the box, and the horizontal location is 16 inches. The coupling is classified as “fair” (2). The worker twists 90 degrees to pick up the product. The job is performed for an 8-hour shift with a frequency rate of 1-lift per minute. Since significant control is not required at the destination, the RWL is only computed at the origin of the lift.

The task variable data are measured and recorded using the ErgoPlus Platform:

Calculation

Results

Results

To conduct ergonomic assessments using the ErgoPlus Platform, you can create a free account here.

To conduct ergonomic assessments using the ErgoPlus Platform, you can create a free account here.

Hazard Assessment

As shown above the RWL for this lifting task is 16.5 lb. The weight to be lifted (25 lb.) is greater than the RWL (16.4 lb.). Therefore, the LI is 25/16.5 or 1.52. This task would be stressful for some workers.

Redesign Suggestions

The worksheet above shows that the multipliers with the smallest magnitude (i.e., those providing the greatest penalties) are .71 for the HM, .71 for the AM, and .75 for the FM. Therefore, the following job modifications are suggested:

- Bring the load closer to the worker to increase HM.

- Move the lift’s origin and destination closer together to reduce the angle of twist and increase the AM.

- Reduce the lifting frequency rate and/or provide longer recovery periods to increase FM.

Assuming that the large horizontal distance is due to the size of the object lifted rather than the existence of a barrier, then the horizontal distance could only be reduced by making the object smaller or re-orienting the object. An alternate approach would be to eliminate body twist by providing a curved chute to bring the object in front of the worker.

Calculation

Results

As shown on the above modified worksheet based on the redesign suggestions, the AM is increased from 0.71 to 1.0, the HM is increased from 0.71 to 0.77, the RWL is increased from 16.4 lb. to 24.9 lb., and the LI is decreased from 1.5 to 1.00. Eliminating body twist reduces the physical stress to an acceptable level for most workers. Alternate redesign recommendations could include: (1) raising the height of conveyor A and/or reducing the height of work bench B; or, (2) Providing good couplings on the containers. For example, the curved chute could also be designed to bring the load to a height of 30 inches. This would increase the VM, DM, and CM values to 1.0, which would reduce the lifting index even further.

Comments

Although several alternate redesign suggestions are provided, reducing the asymmetric angle should be given a high priority because a significant number of overexertion lifting injuries are associated with excessive lumbar rotation and flexion.

Free Ergonomic Assessment Software

Create a free ErgoPlus Platform account to start conducting faster, more accurate ergonomic assessments using the most popular tools.