The following NIOSH Lifting Equation Example is from the NIOSH Lifting Equation Applications Manual has been adapted to show the proper use of the NIOSH Lifting Equation inside the ErgoPlus Platform.

In addition, this example shows how this tool can be used to evaluate body mechanics recommendations and ergonomic redesign suggestions.

To help you follow along, here are links to download our free guides to recommended ergonomic assessment tools and to create a free ErgoPlus Platform account to use the NIOSH Lifting Equation software tool inside.

Now let’s get to work on the example:

Job Description

The worker positions himself midway between the hand truck and the mixing hopper, as illustrated in the picture below. Without moving his feet, he twists to the right and picks up a bag off the hand truck. In one continuous motion, he then twists to his left to place the bag on the rim of the hopper. A sharp-edged blade within the hopper cuts open the bag to allow the contents to fall into the hopper. This task is done infrequently (i.e., 1-12 times per shift) with large recovery periods between lifts (i.e., > 1.2 Recovery Time/Work Time ratio). In observing the worker perform the job, it was determined that the non-lifting activities could be disregarded because they require minimal force and energy expenditure. Significant control is not required at the destination, but the worker twists at the origin and destination of the lift. Although several bags are stacked on the hand truck, the highest risk of overexertion injury is associated with the bag on the bottom of the stack; therefore, only the lifting of the bottom bag will be examined. Note, however, that the frequency multiplier is based on the overall frequency of lifting for all of the bags.

Job Analysis

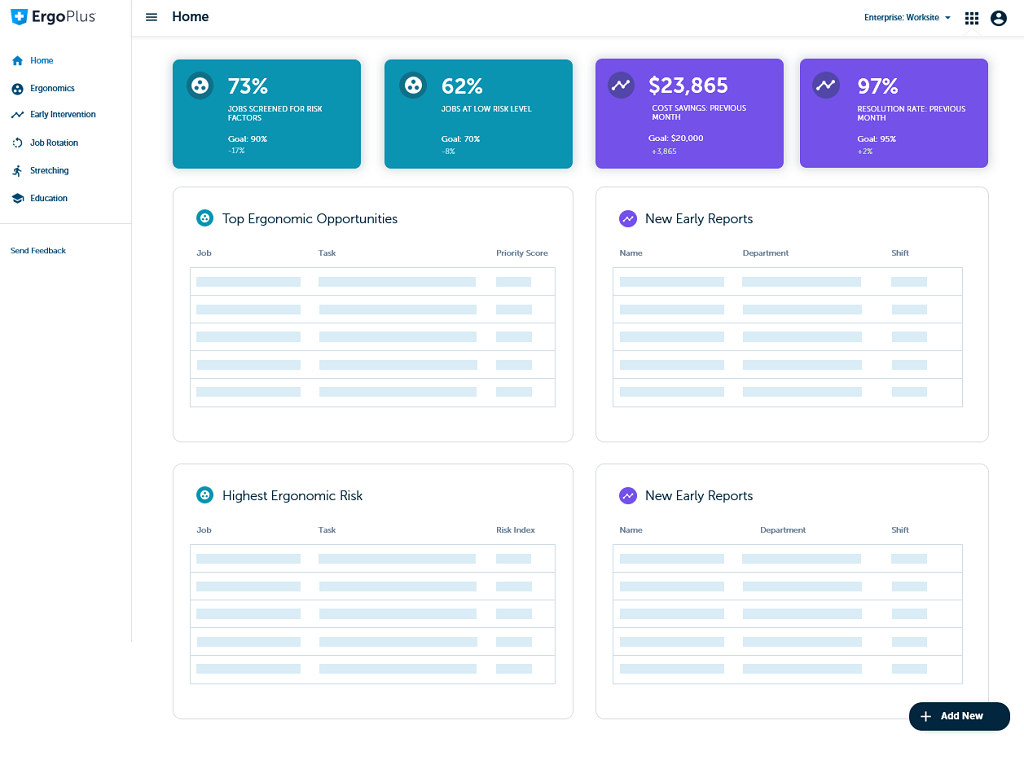

The task variable data are measured and recorded using the ErgoPlus Platform:

To conduct ergonomic assessments using the ErgoPlus Platform, you can create a free account here.

The vertical location of the hands is 15 inches at the origin and 36 inches at the destination. The horizontal location of the hands is 18 inches at the origin and 10 inches at the destination. The asymmetric angle is 45 degrees at the origin and 45 degrees at the destination of the lift, and the frequency is less than .2 lifts/min for less than 1 hour. The coupling is classified as fair because the worker flexes the fingers about 90 degrees and the bags are semi-rigid (i.e., they do not sag in the middle). NOTE: Significant control of the object is not required at the destination of the lift so the RWL is computed only at the origin.

Hazard Assessment

The RWL for this activity is 18.5 lb. The weight to be lifted (40 lb.) is greater than the RWL. Therefore, the LI is 40/18.5 or 2.16. This job would be physically stressful for many industrial workers.

Redesign Suggestions

The smallest multipliers (i.e., the greatest penalties) are .56 for the HM, .86 for the AM, and .89 for the VM. The following job modifications are suggested:

- Bringing the load closer to the worker to increase the HM.

- Reducing the angle of asymmetry to increase AM. This could be accomplished either by moving the origin and destination points closer together or further apart.

- Raising the height at the origin to increase the VM.

If the worker could get closer to the bag before lifting as suggested in #1 above, the H value could be decreased to 10 inches. This would increase the HM to 1.0, the RWL would be increased to 33.3 lb., and the LI would be decreased to 1.20 as shown in the revised calculator results below:

Comments

This example demonstrates that certain lifting jobs may be evaluated as a single-task or multi-task job. In this case, only the most stressful component of the job was evaluated. For repetitive lifting jobs, the multi-task approach may be more appropriate.

Free Ergonomic Assessment Software

Create a free ErgoPlus Platform account to start conducting faster, more accurate ergonomic assessments using the most popular tools.