Ready to implement job rotation in your workplace to reduce risk and prevent injuries? Get started with this step-by-step guide.

(Note: This step-by-step guide provides examples of creating job rotation schedules using a tool we call the Job Rotation Evaluator. To learn more about the tool and to use it for yourself, you can learn more and get access to it here: Learn more about the Job Rotation Evaluator. This guide will still be helpful if you don’t have it, but you’ll save yourself quite a bit of time with the right tool in hand as you create your job rotation schedules.)

Job Rotation Overview

Job rotation is the structured interchange of workers between different jobs, requiring workers to rotate between different workstations or jobs at certain time intervals.

Job rotation increases the variety of tasks required as the worker takes on more duties, enlarging the physical demands and adding variety to the job.

The objective is to provide a consistent and systematic method of developing formal job rotations that are based on the requirements of the jobs being rotated.

It’s important to remember that job rotation doesn’t eliminate ergonomic risk factors. While job rotation is an effective control measure for jobs that have been identified as “problem” or “high-risk” jobs, it is not desirable that ergonomic risk factors are “hidden” by administrative controls.

Obviously, ergonomic problems should be addressed and fixed whenever possible. With the above “caution” being stated, it’s equally important to recognize the many great benefits to implementing job rotation in the workplace.

Benefits of Job Rotation

Many studies have identified a variety of benefits from implementing job rotation including:

- Reduced exposure to focused physical demands of one job.

- Reduced physiological stress, strain, and fatigue to muscle group used for one job.

- Reduces employee exposure to high-risk job demands.

- Reduced MSD incidents and severity.

- Increased innovation and improved work process efficiency.

- Improves employee skill base and increases job assignment flexibility over time.

- Reduced boredom and complacency.

- Increased productivity & quality.

- Reduced absenteeism & turnover.

Potential Barriers to Job Rotation

There are several potential barriers and difficulties with implementing job rotation, the following are some of them:

- Not all jobs and departments are a good fit for job rotation.

- Short-term productivity losses and product quality issues.

- Workers not wanting to rotate because they have an “easier job”.

- Workers not wanting to change jobs or learn new work tasks for a variety of reasons.

- Workers not wanting to give up “their job” to others.

- Workers not qualified for some jobs due to restrictions or ability.

- Union or other workplace policies related to job bidding and compensation.

- Supervisors are not convinced that the benefits are worth the perceived costs.

- Supervisors perceive that implementation and management of job rotation is very difficult.

- Group leaders and trainers tend to focus on the short term costs rather than the long-term benefits, and perceive that the costs are too high for them verses the benefits.

- Supervisors and group leaders not wanting to “fight” employees who don’t want to rotate.

Misconceptions about Job Rotation

Misconception #1: “Job rotation will fix ergonomic issues.”

- Fact: Job rotation is NOT a substitute for an ergonomic improvement process.

Misconception #2: “Quality and productivity will suffer with implementation of a job rotation program.”

- Fact: Quality and productivity gains can be realized thru an effective job rotation program.

Misconception #3: “Job rotation is hard to manage.”

- Fact: Once effective rotations are set, job rotation is no harder to manage than regular work assignments. If fact, managers have much greater flexibility when workers are trained to perform a variety of jobs.

Misconception #4: “Job rotation is easy to design.”

- Fact: Effective design is one of the most important and difficult aspects of a job rotation program. The rotation sequence and frequency should be based on a specialist’s evaluation of various job factors including: muscle groups used, forces, postures, repetition, sustained exertions, tools utilized, and skill / training requirements.

Misconception #5: “Job rotation will not be accepted by management or employees.”

- Fact: While it’s true that this can be a hard sell (especially if the company safety culture is not strong), the benefits of implementing job rotation frequently exceed the costs. Managers and employees will accept this program provided that they fully understand the benefits of job rotation, and upper management is fully committed to it.

1: Determine Jobs Suitable for Rotation

Consult management, supervisors, group leaders, safety & ergonomics team members and employees to determine which departments and jobs are suitable for a job rotation program.

Job rotation can be used reactively and proactively.

Reactive job rotation reduces employee exposure to jobs that have been identified as “high-risk” based on an objective ergonomic assessment. Rotation can be used until engineering controls are implemented.

Proactive job rotation can be implemented to prevent muscle fatigue due to exposure to job tasks that focus the work load on single muscle groups, and for additional benefits outlined above.

2: Select Method for Job Rotation Analysis

OSHA’s ergonomic guidelines state that if job rotation is utilized, the jobs should be reviewed by a qualified person to determine the muscle-tendon groups that are used to perform the job.

A “qualified person” according to OSHA, is “One who has thorough training and experience sufficient to identify ergonomic hazards in the workplace and recommend an effective means of correction; for example, a plant engineer fully trained in ergonomics – not necessarily an ergonomist.”

There is no scientifically proven system or protocol for determining job rotation guidelines and schedules. However, we have developed a semi-quantitative evaluation method of scoring job exertion which we feel is an effective tool which can be used as a means to help determine optimal job rotation sequence and schedules.

I want to emphasize that this is not a scientifically proven approach. However, we have used this very simple and practical method to evaluate job rotation schedules for many years with excellent results. Job rotation evaluations frequently occur in the establishment phase of the MSD prevention process. Proactive job rotation is often considered “low hanging fruit” and most companies will benefit from implementing job rotation immediately or as soon as possible.

This doesn’t mean however, that job rotation should be implemented without considering the physical demands of the job and other factors. That’s where our method shines.

3: Use the Job Rotation Evaluator to Easily Create Job Rotation Schedules Based on Job Demands

We call our method the “Job Rotation Evaluator”, which is a calculator tool that uses some of the general principles from the Job Strain Index¹ to quickly evaluate the exertion level required by the major muscle groups. In order to keep the job rotation evaluations quick and simple, our method only uses three (force, posture, repetition) of the six index variables used in the Job Strain Index, but considers all major muscle groups.

Our evaluations assume 8 hours of duration exposure to each job evaluated. Certainly, we recommend that the evaluator take into consideration all high risk job task variables when performing job rotation evaluations.

The Job Rotation Evaluator considers the following muscle groups and functional roles, and evaluates job exertion levels for each group.

Muscle Group Functional Role:

Neck / Upper Back: Movement and postural stabilization of the head and neck (flexion/extension, lateral flexion, rotation), and postural stabilization of the shoulders and upper torso. Primary risks are: 1) sustained/repeated neck flexion, 2) lifting with arms up and extended.

Upper Arms / Shoulders: Movement of the elbow (flexion/extension) and shoulder (flexion/extension, abduction/adduction, internal/external rotation). Primary risks are: 1) lifting with biceps (elbow flexion), 2) forceful, repeated , or sustained shoulder elevation (flexion or abduction) greater than 45ᵒ, 3) forceful or repeated shoulder internal/external rotation.

Forearm / Elbow: Twisting of forearm (supination/pronation), stabilization and movement of the wrist (flexion/extension). Primary risks are: 1) forceful end-range forearm twisting, 2) forceful, repeated, or sustained wrist/forearm extension, 3) forceful lifting in palm up (supinated) forearm position.

Wrist / Fingers: Movement of the wrist (flexion/extension, radial/ulnar deviation) gripping, pinching, finger extension. Primary risks are: 1) forceful, repeated flexion and ulnar deviation, 2) forceful and repetitive gripping and pinching.

Trunk / Lower Back: Movement and stabilization of the trunk and lower back (flexion/extension, side bending, and twisting). Primary risks are: 1) frequent or sustained forward bending posture, 2) heavy lifting and carrying tasks.

Legs: Movement, balance, and stabilization. Primary risks are: 1) prolonged standing on hard surfaces, 2) foot pedal control activation.

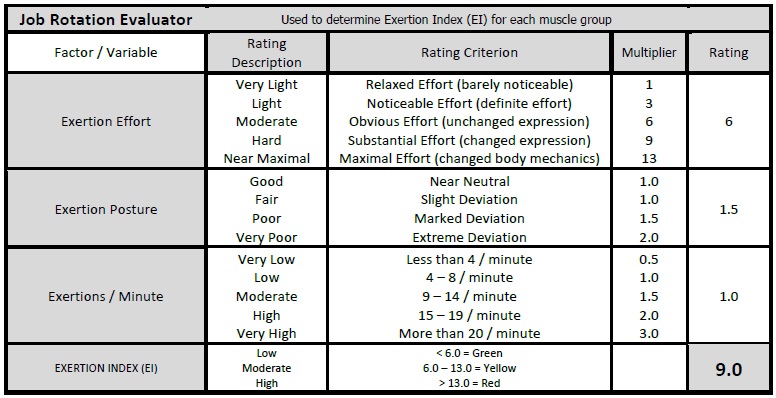

Calculator Method

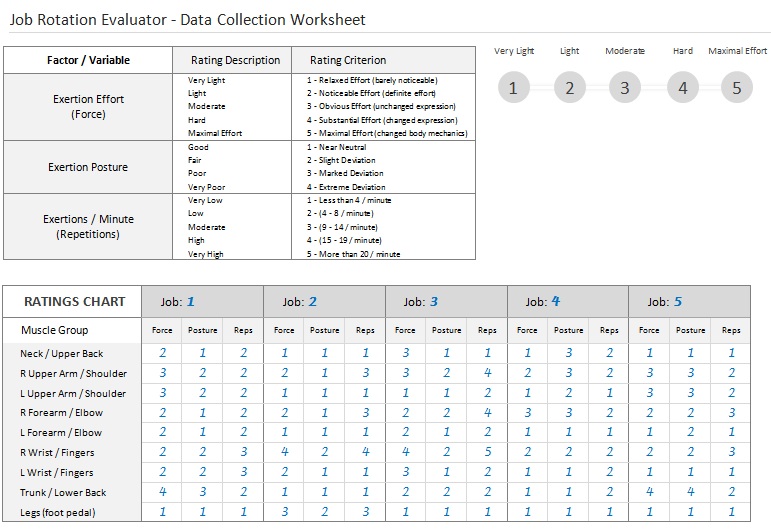

For each job being considered in the rotation, each of the above muscle groups is evaluated for what I call “The big 3” ergonomic risks factors of exertion effort, exertion posture, and exertions per minute (force, posture, repetition). Each of these three variables is given a rating value or multiplier based on the rating criterion outlined in the example chart below. After the three ratings are determined, these values are multiplied to determine the Exertion Index (EI) for this muscle group on this job. In the example below, the product of the ratings is 9.

6 x 1.5 x 1.0 = 9.0

The EI is then compared to a gradient that estimates the level of task risk: Less than 6.0 = low risk (green), 6.0 – 13.0 = moderate risk (yellow), and greater than 13.0 = high risk (red). An EI is calculated for each muscle group for all jobs being considered for rotation.

Job Rotation Evaluator Used to determine Exertion Index (EI) for each muscle group

Using the Job Rotation Evaluator

Step 1: Determine Variable Ratings

You should prepare for the job evaluation by interviewing and observing workers to gain a complete understanding of all required tasks. You will then use the data collection worksheet to record ratings and measurements for the three variables needed to calculate the Exertion Index (EI).

Exertion Effort – This rating is based on a perceived exertion scale which is similar to the Borg Scale², with fewer choices (5 rather than 10 -15). For each muscle group, you will rate the level of exertion based on asking employees about their perception and your observations. In most cases, you can can perform work tasks (ask first) for few cycles so you can get a personal feel for the level of exertion required. Don’t over-think this part. Consult employees, observe employees, perform the task yourself if possible, and then select the appropriate rating based on your professional judgment.

Exertion Posture – Base this rating upon observation of work tasks along your knowledge of human movement and joint posture.

Exertions / Minute – Determine the frequency of exertions for each muscle group by counting the average number of exertions in a short sampling period, and then dividing the total number of exertions by the number of minutes observed For example, count the total number of exertions in a typical 5 minute period of time and divide that total number by 5. Alternatively, you can ask for production records to determine the number of exertions per a typical 8-hour shift and divide that total by 60.

Note: As we have already stated, some jobs could have other variables that are not evaluated by this tool that may be a concern. By all means, please don’t ignore any additional risk factors that may be present.

For example: If you get an EI of 12.0 which is considered moderate risk (yellow) for a muscle group (based on the criterion we use) but notice that the job also requires a prolonged exertion that is of concern, you may want to increase the risk level to high (red) for that muscle group. So, use a conservative approach along with your professional knowledge and best judgment to make the final determination.

Step 2: Determine Exertion Index (EI) for Muscle Groups

You are now ready to determine the EI for each muscle group and job using our Job Rotation Evaluator (Excel). Simply select the appropriate rating criterion on the worksheet for each muscle group. Repeat this process using a different worksheet for every job being considered for rotation into the worksheet.

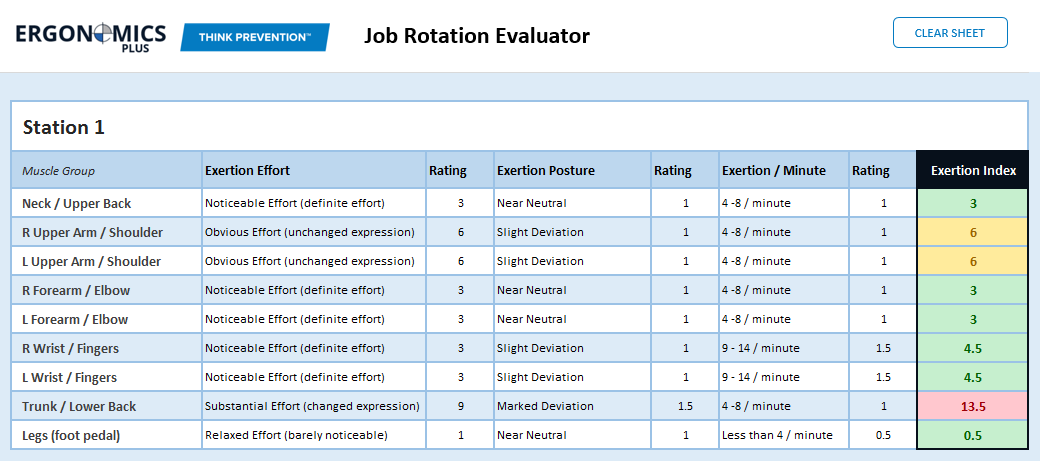

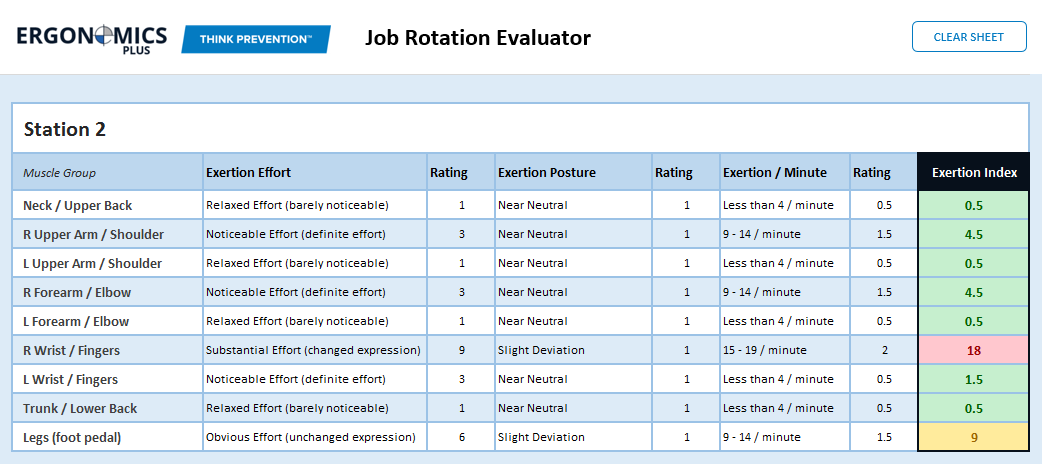

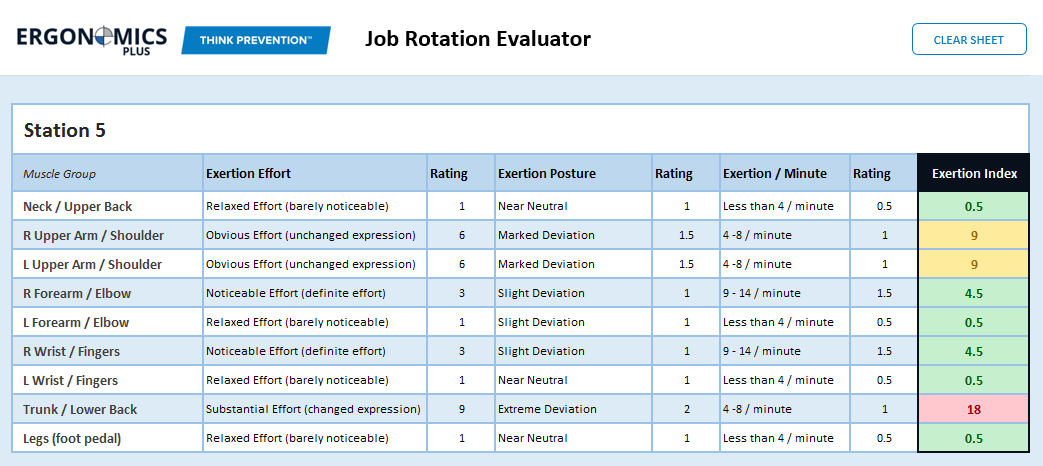

As we have already discussed and shown above, the product of the three multiplier ratings produces a total value which we call the Exertion Index (EI). The EI is then compared to a gradient that estimates the level of task risk:

- Less than 6.0 = low risk (green)

- 6.0 – 13.0 = moderate risk (yellow)

- Greater than 13.0 = high risk (red)

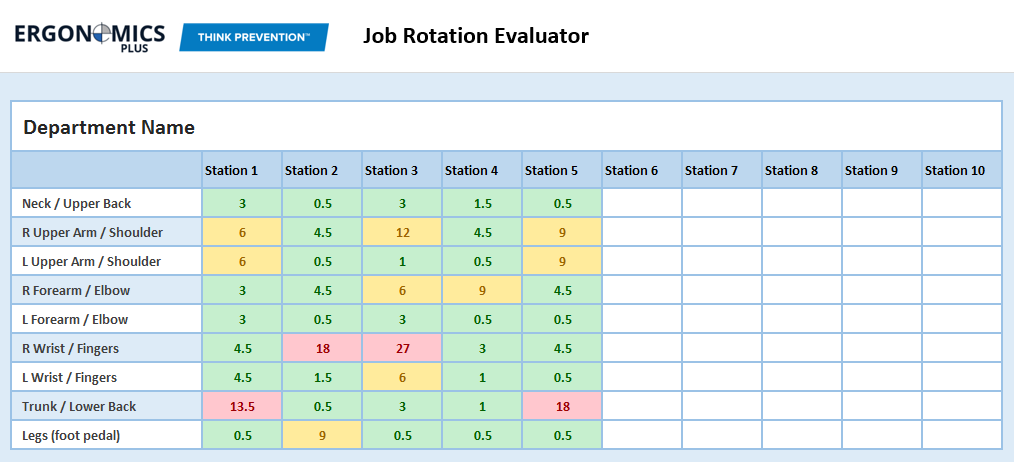

After you have completed the inputs, the EI for each job will automatically transfer to the Department Chart as shown below. This single chart will allow an easy comparison of the exertion levels by muscle group for all the jobs being considered for rotation.

Step 3: Determine Job Rotation Sequence

By definition, job rotation occurs when workers perform two or more different jobs over a pre-determined period of time. The rotation sequence or schedule should be based on the Job Rotation Evaluator tool results to ensure that the different jobs in the rotation do not present the same ergonomic stressors to the same parts of the body (muscle-tendon groups).

The objective is to provide a consistent and systematic method for job rotations that are based on the requirements of the jobs. The ideal rotation schedule is based on the following criterion:Acceptable rotations:

- Green ↔ Green

- Green ↔ Yellow

- Green ↔ Red

Avoid if possible:

- Yellow ↔ Yellow

Unacceptable rotations:

- Red ↔ Yellow

- Red ↔ Red

Step 4: Determine Frequency of Rotation

A variety of factors should be considered in order to determine the best frequency of rotation. Rotations lasting 1-2 hours are commonly effective because this fits in well with break sequences. Generally, multiple rotations within the work shift is more effective than daily or weekly rotations. However, some specialized jobs with a higher learning / training curve may need to be rotated less frequently such as daily or weekly. Manufacturing and assembly objectives must be considered as well, so you will need to work with management to determine what frequency would work best for the group of jobs being considered for rotation.

Step 5: Management and Employee Review

The job rotation sequence and frequency recommendations should be reviewed by affected managers and employees. All suggestions and concerns should be taken into consideration, and modifications should be made if necessary.

Step 6: Training and Implementation

Employees may need to undergo a training process for new tasks that will be performed with the job rotation program to ensure that they are fully qualified to perform all jobs. When training is complete and all employees understand the program, you are ready to implement.

Step 7: Follow-up Evaluation

Post-implementation follow-up is necessary to ensure that the rotation is effective and employees are not having difficulty performing new tasks. Conduct follow-up interviews and surveys with managers and employees and compare other metrics such as efficiency, quality, injury rates, turnover, and employee satisfaction to determine effects of the job rotation.

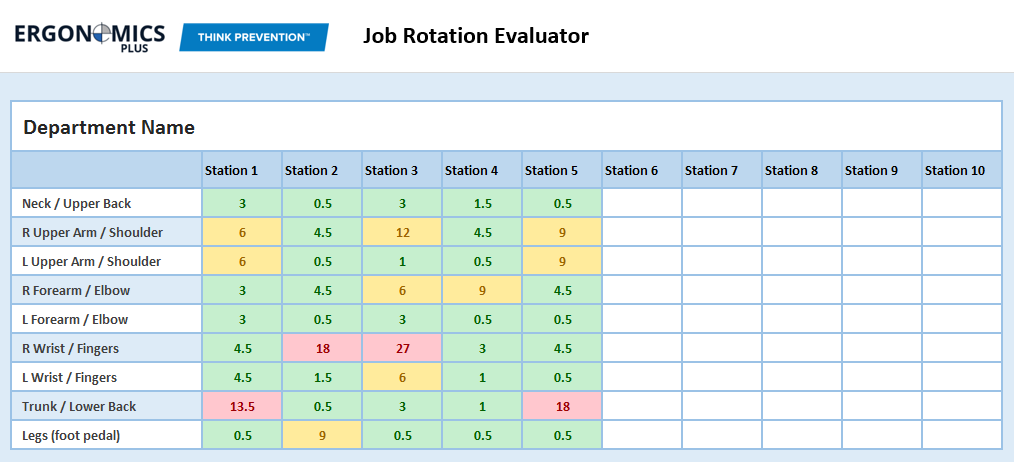

Job Rotation Evaluator Example

This example is an electric panel board assembly line that has five workstations with varied job demands.

Step 1: Determine Variable Ratings

Prepare for the job evaluation by interviewing and observing workers to gain a complete understanding of all required tasks. You will then use the data collection worksheet to record ratings and measurements for the three variables needed to calculate the Exertion Index (EI). See instructions on page 5 for detailed instructions regarding this step. Example data collection worksheet is pictured below:

Step 2: Determine Exertion Index (EI) for Muscle Groups

Now you are now ready to use the Job Rotation Evaluator to determine the EI for each muscle group. Use the data collection worksheet values to select the appropriate rating criterion on the worksheet for each muscle group. Repeat this process using a different worksheet for every job being considered for rotation into the worksheet as outlined below:

Station 1 (view full size image):

Station 2 (view full size image):

Station 3 (view full size image):

Station 4 (view full size image):

Station 5 (view full size image):

Step 3: Determine Job Rotation Sequence

The rotation sequence should be based on the Job Rotation Evaluator tool results to ensure that the different jobs in the rotation do not present the same ergonomic stressors to the same parts of the body (muscle-tendon groups). The objective is to provide a consistent and systematic method for job rotations that are based on the requirements of the jobs. To determine the best sequence from a muscle group exertion standpoint, use the Department Chart from the Job Rotation Evaluator. The example chart is shown below:

The ideal rotation sequence is based on the following criterion:

Acceptable rotations:

- Green ↔ Green

- Green ↔ Yellow

- Green ↔ Red

Avoid if possible:

- Yellow ↔ Yellow

Unacceptable rotations:

- Red ↔ Yellow

- Red ↔ Red

In this example, the Job Rotation evaluator identifies two Red ↔ Red rotations to avoid. There were no Red ↔ Yellow rotation possibilities for the same muscle group.

Unacceptable rotations:

Job 2 ↔ Job 3 (Red ↔ Red)

Job 5 ↔ Job 1 (Red ↔ Red)

Recommended Rotation Sequence:

There are typically several sequence possibilities. This is the recommended rotation sequence based on the Job Rotation evaluation in this example:

1 → 2 → 4 → 5 → 3 → back to 1

This rotation sequence was developed to avoid all Red ↔ Red rotations and Red ↔ Yellow rotations.

Step 4: Determine Frequency of Rotation

A 2-hour rotation schedule was recommended in this case based on manufacturing objectives, training requirements, and to coincide with breaks.

Step 5: Management and Employee Review

You should always review the job rotation sequence and frequency recommendations with affected managers and employees. All suggestions and concerns should be taken into consideration, and modifications in your recommendations should be made if necessary.

Step 6: Training and Implementation

Employees may need to undergo a training process for new tasks that will be performed with the job rotation program to ensure that they are fully qualified to perform all jobs. When training is complete and all employees understand the program, you are ready to implement.

Step 7: Follow-up Evaluation

Post-implementation follow-up is necessary to ensure that the rotation is effective and employees are not having difficulty performing new tasks. Conduct follow-up interviews and surveys with managers and employees and compare other metrics such as efficiency, quality, injury rates, turnover, and employee satisfaction to determine effects of the job rotation.

Save Time and Get More Done With the Job Rotation Evaluator

Job rotation is an important control to prevent injuries in the workplace, but it can be difficult to create a schedule that truly reduces risk and meets everyone’s needs.

Without the right tool, creating a schedule that works can be a daunting and time-consuming task. You have to take into account the physical demands of the job, employee availability, and departmental needs. It can be hard to find a solution that works for everyone.

The ErgoPlus Job Rotation Evaluator makes creating job rotation schedules easy. It takes into account the physical demands of the job and makes it easy for you to schedule employees in a way that reduces risk and prevents injuries.

Learn more and get access to the Job Rotation Evaluator →References

¹ J. Steven Moore and Arun Garg, “The Strain Index: A Proposed Method To Analyze Jobs For Risk Of Distal Upper Extremity Disorders”, American Industrial Hygiene Association Journal, 56:443-458 (1995).

² Borg, G. (1998). Borg’s Perceived Exertion and Pain Scales. Champaign, IL:HK. Can be ordered from: Human Kinetics. In the USA: P.O. Box 5076, Champaign, IL 61825-5076, and in Europe: P.O. Box IW14, Leeds, LS16 6TR, UK

3 Washington State Department of Labor and Industries; Job Rotation System; Dan MacLeod and Eric Kenndy; 1993