Struggling to prevent musculoskeletal disorders (MSDs) at your worksite? Read this article to learn how to use the hierarchy of controls as a framework to reduce MSD risk in your workplace to prevent these injuries.

Table of Contents

Introduction

Does your worksite struggle to prevent MSDs? If so, you certainly aren’t alone. MSDs are common and costly injuries for companies and their employees. MSDs cost employers billions of dollars a year in medical costs and lost productivity. These injuries are also painful experiences for employees and can lead to many negative downstream consequences in their life. They are the most common causes of disability, early retirement, and limitations to gainful employment.

Fortunately, these injuries and their downstream consequences can be prevented. One very commonly used approach to this is to use the hierarchy of controls as a framework to reduce MSD risk in your workplace. In this article, you’ll learn about how to use the hierarchy of controls for MSD prevention at your worksite.

The Cost of MSDs

Why include the cost of MSDs in an article about implementing control measures? MSDs are a problem worth solving and usually solving a problem of this magnitude requires a budget. Many ergonomic improvements can be done at a very low cost, but not all control measures are going to be cheap. Understanding what MSDs are costing you, therefore, is a critical step to take so that you can make the business case for control measures.

A recent report from the National Safety Council shows us that:

- Injuries caused by heavy lifting cost U.S. employers over $13 billion per year

- Injuries caused by awkward postures cost U.S. employers $4.71 billion per year

- Injuries caused by repetitive motions cost U.S. employers $1.66 billion per year

You know what they say … a billion here, a billion there, and pretty soon it adds up to real money.

The good news from the NSC report? Every dollar spent on prevention generates twice the return or more. In other words, ergonomic improvements are a sound investment. Use this information to gain support for your MSD prevention efforts!

Understanding MSD risk factors

Now we know that MSDs are common and costly. This means you can make a solid business case for investing in ergonomics. So are we ready to talk about using the hierarchy of controls yet? Nope, not yet.

First, we need to talk about the causes of MSDs. Understanding MSD risk factors is an important first step to putting a prevention strategy in place using the hierarchy of controls. This is because the hierarchy of controls is most effective when it is part of a comprehensive, strategic approach to addressing MSD risks across your entire worksite and workforce.

Simply put, you need to understand the risk factors at play to effectively implement control measures for them at scale.

So, what are MSD risk factors?

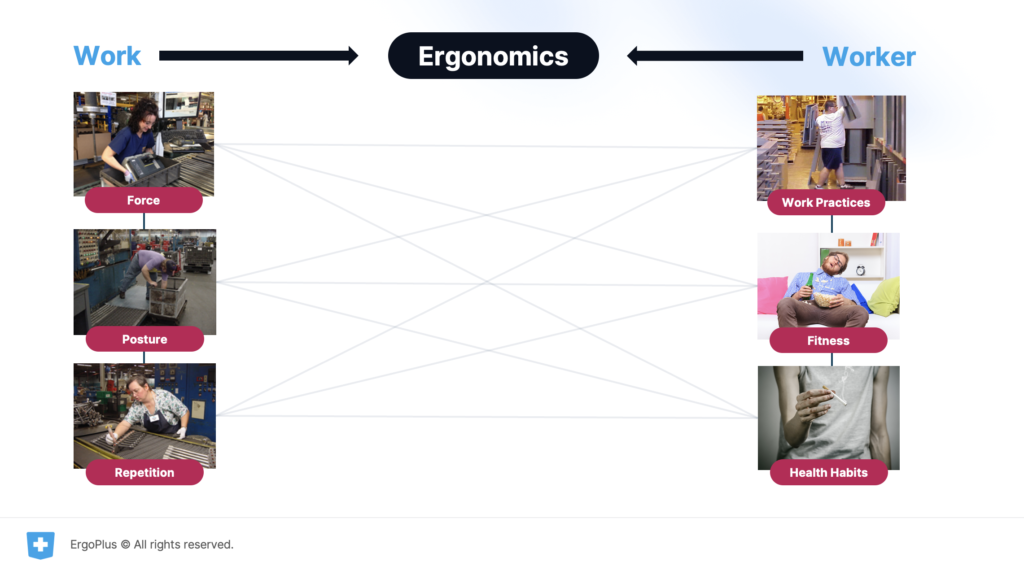

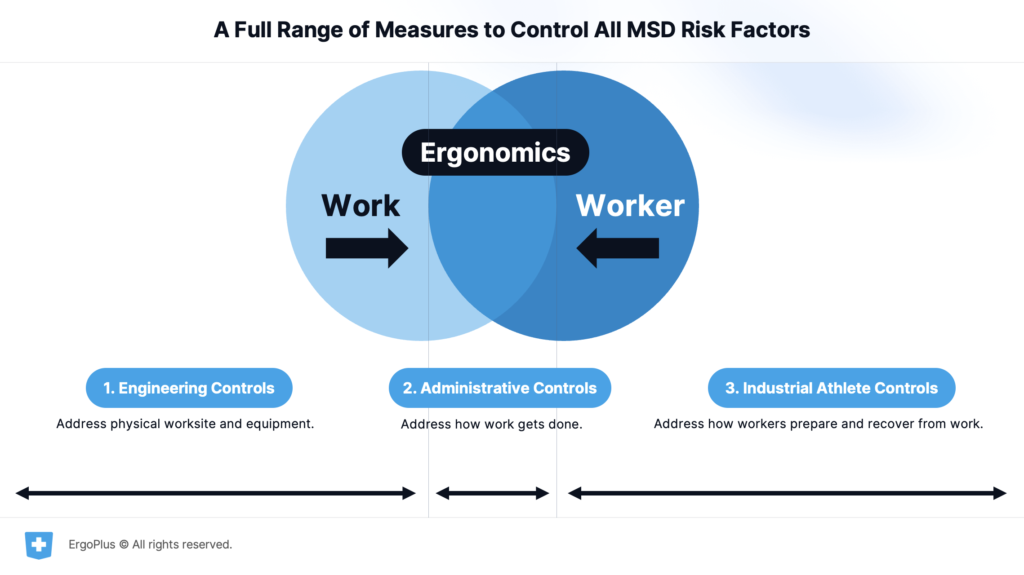

Many causative risk factors contribute to musculoskeletal disorders. Consider this: according to NIOSH, ergonomics is the science of designing the workplace to fit within the capabilities of the working population. So occupational ergonomics is fundamentally about the interaction between the work and the worker, and the research tells us that both the work and the worker bring risks into this interaction.

MSD Risks relating to the work

The three primary ergonomic risk factors are excessive force, awkward postures, and high repetition. Additional risk factors include contact stress, impact stress, and hand-arm vibration.

MSD Risks relating to the worker

Individual risk factors include work practices, physical conditioning, age, gender, previous MSD history, and activities outside of work.

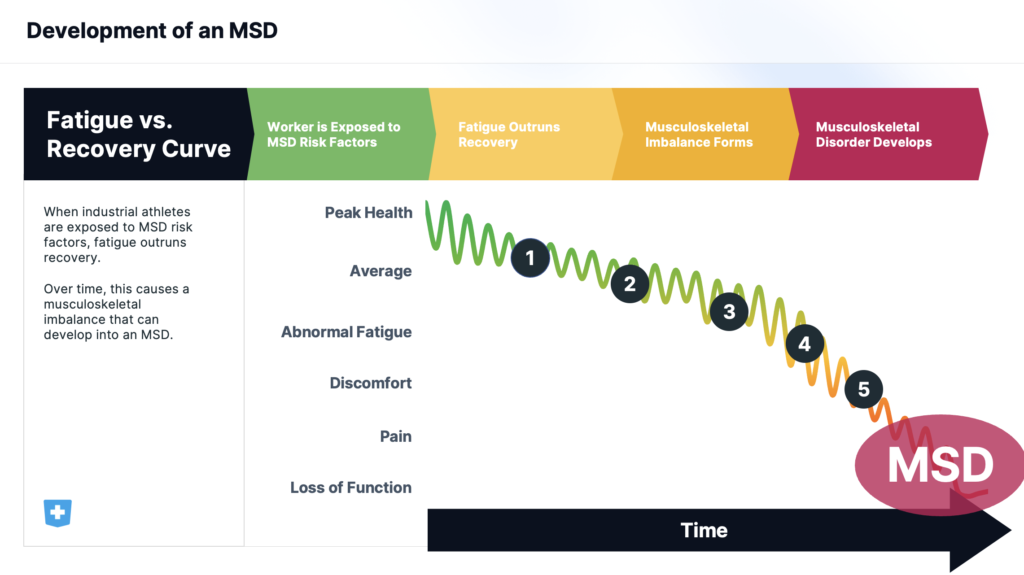

The development of an MSD is a result of exposure to MSD risk factors

MSDs develop over time as a result of exposure to these risk factors. Early signs of MSDs include pain, tenderness, swelling, stiffness, loss of capacity, reduced range of motion, tingling, and numbness. If these early signs aren’t addressed, they can eventually lead to an MSD.

What Is the Hierarchy of Controls for MSDs?

Okay, now we’re ready for the hierarchy of controls!

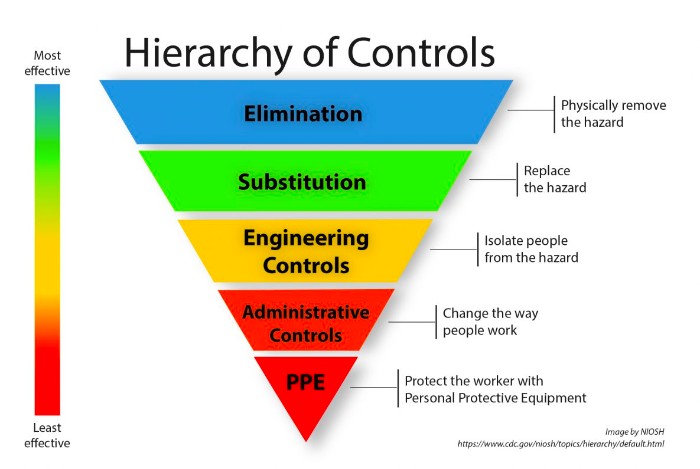

The hierarchy of controls is a framework that can be used to reduce the risks of any hazard. It ranks control methods from the most effective to the least effective.

This is the traditional hierarchy of controls from the NIOSH website that you are likely familiar with. It’s not a perfect fit for MSD risks, so here’s our take on a modified version:

The same basic idea holds in this version, with the most protective controls at the top. Engineering Controls –> Administrative Controls –> Industrial Athlete Controls.

The nature of MSDs are more complex and multifactorial than many safety hazards, so you’ll notice that it’s often necessary to apply a combination of control methods.

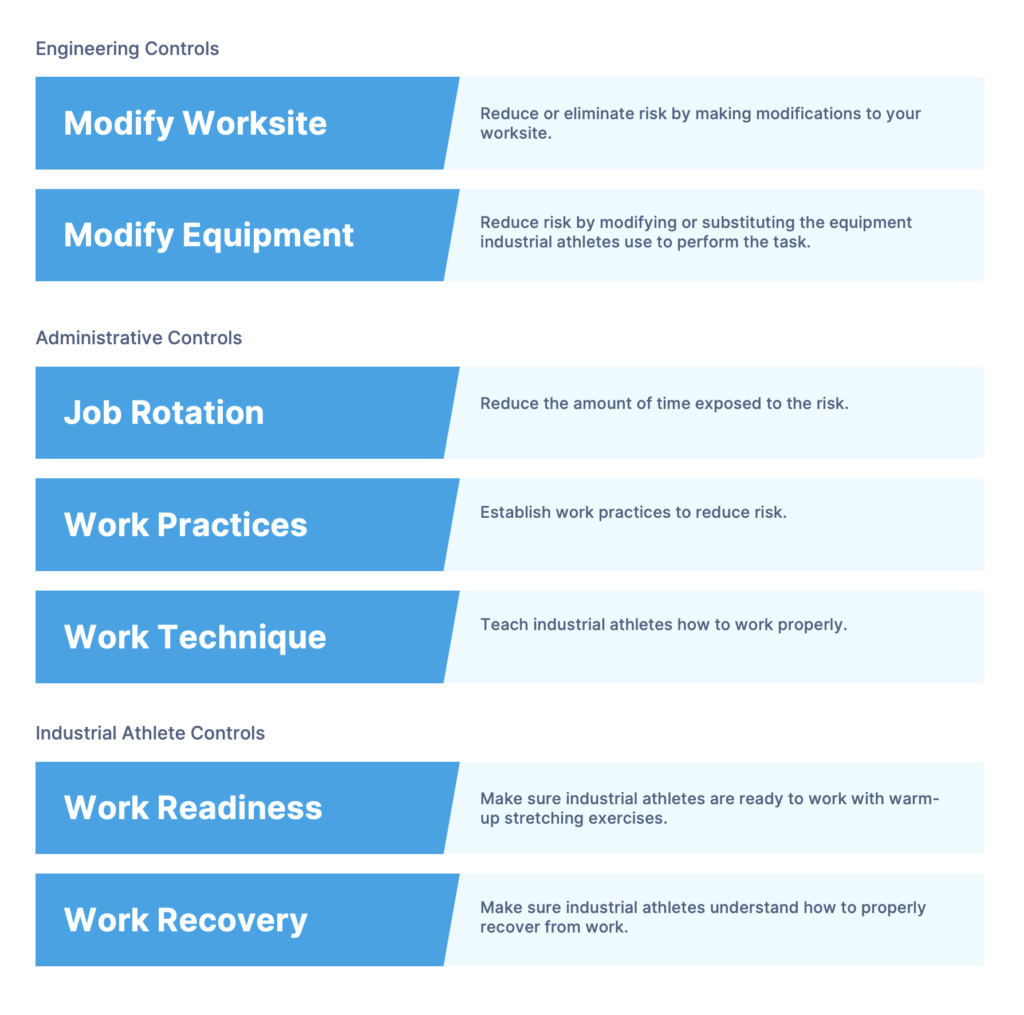

Engineering controls

Engineering controls address the physical worksite and the equipment used to perform the work.

Modify Worksite: Reduce or eliminate the risk by making modifications to your worksite.

Example: Installing a conveyor belt to move product from point A to point B.

Modify Equipment: Reduce risk by modifying or substituting the equipment industrial athletes use to perform the task.

Example: Provide a hand cart to move product from point A to point B.

Administrative controls

Administrative controls address the time spent doing the work and how the work should be performed.

Job Rotation: Reduce the amount of exposure to risk.

Example: Use the Job Rotation Evaluator to create a job rotation schedule based on job demands.

Work Practices: Establish work practices to reduce risk.

Example: Create a work practice to execute a two-man lift and train industrial athletes on how to execute.

Work Technique: Teach industrial athletes how to work properly.

Example: Conduct training that teaches industrial athletes how to move, lift, lower, push, pull, carry, and operate tools and equipment properly.

Industrial athlete controls

Industrial athlete controls address how the industrial athletes performing the job prepare to work and recover from work. It’s their musculoskeletal system we’re concerned with, after all.

Work Readiness: Make sure industrial athletes are ready to work with warm-up stretching exercises.

Example: Whether your warm-up stretching program is mandated or not, industrial athletes should be trained on how to properly prepare their body and mind for work.

Work Recovery: Make sure industrial athletes understand how to properly recover from work and provide ways for them to report early signs of fatigue and discomfort so they can receive further guidance on musculoskeletal recovery methods.

Example: Industrial athletes should know how to care for their musculoskeletal system and learn how to identify the early warning signs of fatigue and discomfort that could lead to an MSD. They should be encouraged to report any early fatigue or discomfort so additional control measures can be put in place to reduce risk.

Full range of controls

The important part of this customized version of the hierarchy of controls specifically for MSDs is that it provides a comprehensive set of control measures, not leaving anything to chance. If your goal is to maximize your MSD prevention efforts, you should always have a control measure in your toolbox and you’ll often be using more than one.

Implementing MSD Controls In Your Workplace

As we mentioned before, the hierarchy of controls is most effective when it is part of a comprehensive, strategic approach to addressing MSD risks across your entire worksite and workforce.

This is an important concept you don’t want to miss. The hierarchy of controls is typically meant to be applied to a single task where a known hazard is present. This is the tactical approach, and you should certainly use it this way. But you also should consider how you are going to implement control measures at a strategic level.

The reality is that you likely have tens or hundreds of jobs at your worksite that have significant MSD risks present. Your job, then, is to implement control measures at scale before injuries occur. To accomplish this, you’ll need a smart MSD prevention strategy (where strategy is defined as choosing a sequence of actions that leads to the desired result).

MSD prevention strategy is about having a full toolbox of control measures available to you and sequencing them in the correct order. This might be counterintuitive at first, but what you’ll often find is that it makes sense to flip the hierarchy of controls upside down as you consider implementing controls at scale.

The main reason for this? Time and money, of course (as is the case with most things).

The ideal situation would be to identify and eliminate all MSD risk factors from every single task at your worksite immediately, perfectly following the hierarchy of controls. While that ideal is a great thing to strive for, I’ve never seen it happen. For one, the complete elimination of all workplace risk factors would take a significant amount of time and resources. It’s simply impossible to do immediately. Second, there are many jobs where engineering controls aren’t feasible. And third, as long as a person with a musculoskeletal system is doing the job there are at the very least individual risk factors at play.

What all of this means is that in most cases you’ll need to implement the controls at the bottom of the hierarchy as a foundation while you simultaneously execute tactical engineering controls that modify your physical worksite.

Sequencing MSD Prevention Controls Across Your Entire Worksite and Workforce

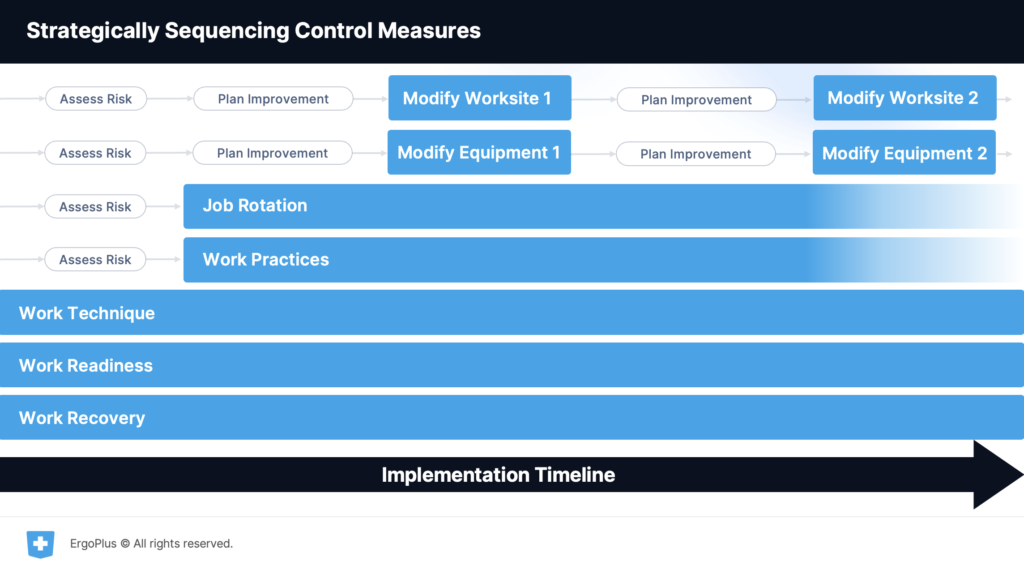

The graphic above is an example of how you can implement a full set of control methods at your worksite over time. While the entire process begins at the same time, you can see that the control methods at the bottom of the hierarchy (which are easier and faster to implement) were implemented first across the entire worksite while the control methods at the top of the hierarchy (harder and slower to implement) are implemented over time to specific jobs and tasks.

You can think of the control methods at the bottom end of the hierarchy as a foundation you can build on. The important thing here is not to be satisfied after implementing controls from the bottom of the hierarchy. The most protective controls are at the top of the hierarchy and you should focus your efforts on those engineering controls as much as possible.

While industrial athletes should always be trained on Work Recovery, Work Readiness, and Work Technique, other control methods like Job Rotation and specific Work Practices like a two-man lift can be faded out over time as engineering controls are implemented.

Main Takeaways for the Hierarchy of Controls for MSD Prevention

– MSDs are common and costly injuries. They cost U.S. employers billions of dollars per year and U.S. workers painful and possibly life-changing injuries.

– MSDs are caused by a wide variety of risk factors that are well-researched and understood. They include risk factors related to the workplace and risk factors related to the worker.

– The hierarchy of controls is a framework for implementing control measures to reduce MSD risk factors. The solutions to MSDs are well-known and readily available. It’s up to you to proactively implement them before injuries occur.

– Maximizing your MSD prevention efforts at your worksite requires a strategic sequencing of control measures that address your physical worksite and equipment, how the work gets done, and how industrial athletes prepare and recover from the work.

– Because the nature of MSDs are complex and multifactorial, you’ll often need to have multiple control measures in place.